3D printing session started off by Mr. Fran briefing us about types of 3D printers, their applications and softwares. Then he asked us to download Cura 3D printing software.

To download Cura software access Ultimaker Cura software and hit the download button.

After we had downloaded the software, Mr.Fran started talking about the settings within the software. He recomended us to make the following:

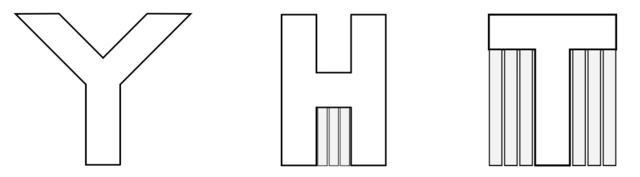

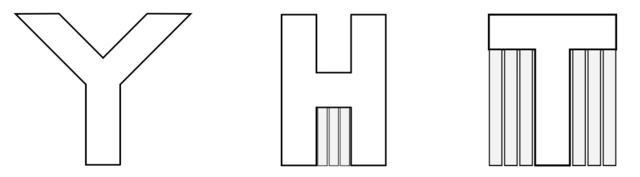

If a piece on the shape inclined at an angle <= 45 degree from the surface of the glass, then generate a support.

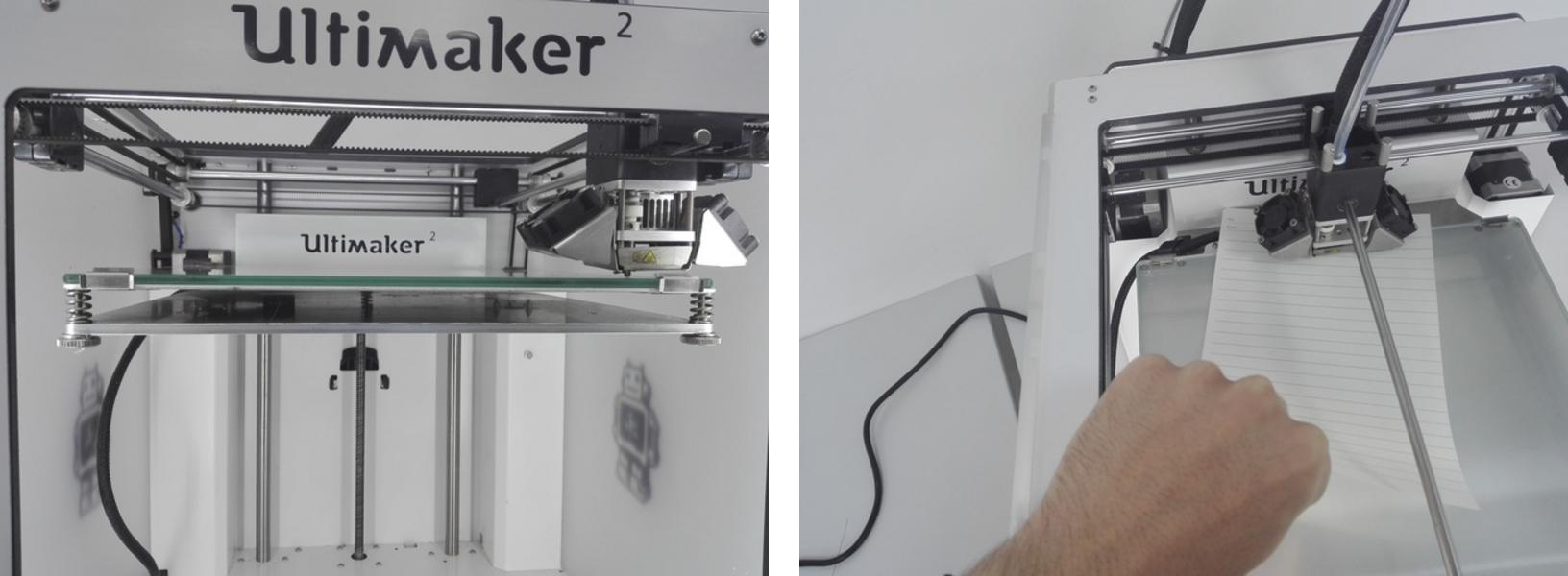

Before turning on the machine we have to clean it, Mr. Fran told us that when the machine is clean, people will respect the machine. We used alcohol based cleaners to clean the 3D printer. Also, we have to make sure that all the rods are fixed and the belts are tied.

After we cleaned the printer and checked it out we turned it on and made the following procedures:

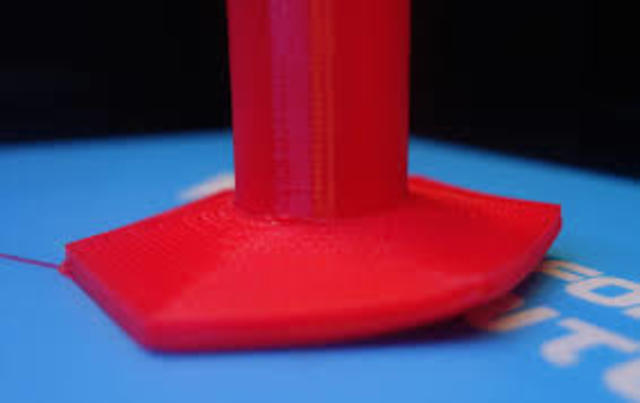

Insert material.

But firstly I have to make sure that the filament are not stock while pulling him out.

Then I set the layer height in the printer through build plate option.

After that I slided the paper between the build-plate and the nozzle until I felt a bit resistance.

Then I chose move the material option and started rotating the button, and once it out from the nozzle I have to touch the filament to see if it is smooth. It was smooth, so my printer now is ready to print.

I have summarized all the precautions that I have heard from Mr. Fransisco during working on the 3D-printers.

A 3D scanner is a device that analyses a real-world object or environment to collect data on its shape. The collected data can then be used to construct digital 3D models.

I download the scanning software on window's operating system by accessing cubify.com, then I made the following procedure: